Page 190 - PROTEC PLASTICS UK 33

P. 190

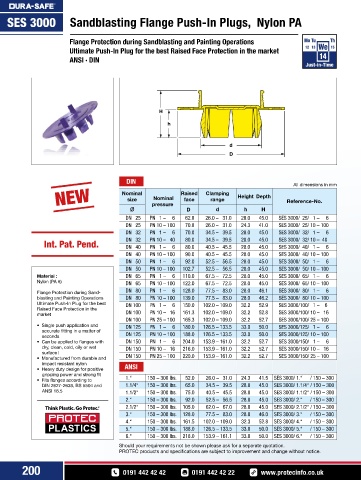

Sandblasting Flange Push-In Plugs, Nylon PA

Flange Protection during Sandblasting and Painting Operations

Ultimate Push-In Plug for the best Raised Face Protection in the market

ANSI · DIN

DIN All dimensions in mm

NEW Nominal Nominal Raised Clamping Height Depth Reference-No.

face

range

size

pressure

D d h H

DN 25 PN 1 – 6 62.0 26.0 – 31.0 28.0 45.0 SES 3000/ 25/ 1 – 6

DN 25 PN 10 – 100 70.0 26.0 – 31.0 24.3 41.0 SES 3000/ 25/ 10 – 100

DN 32 PN 1 – 6 70.0 34.5 – 39.5 28.0 45.0 SES 3000/ 32/ 1 – 6

Int. Pat. Pend. DN 32 PN 10 – 40 80.0 34.5 – 39.5 28.0 45.0 SES 3000/ 32/ 10 – 40

SES 3000/ 40/ 1 – 6

45.0

28.0

80.0

40.5 – 45.5

DN 40

PN 1 – 6

DN 40 PN 10 – 100 90.0 40.5 – 45.5 28.0 45.0 SES 3000/ 40/ 10 – 100

DN 50 PN 1 – 6 92.0 52.5 – 56.5 28.0 45.0 SES 3000/ 50/ 1 – 6

DN 50 PN 10 – 100 102.7 52.5 – 56.5 28.0 45.0 SES 3000/ 50/ 10 – 100

Material : DN 65 PN 1 – 6 110.0 67.5 – 72.5 28.0 45.0 SES 3000/ 65/ 1 – 6

Nylon (PA 6) DN 65 PN 10 – 100 122.0 67.5 – 72.5 28.0 45.0 SES 3000/ 65/ 10 – 100

Flange Protection during Sand- DN 80 PN 1 – 6 128.0 77.5 – 83.0 28.0 46.1 SES 3000/ 80/ 1 – 6

blasting and Painting Operations DN 80 PN 10 – 100 139.0 77.5 – 83.0 28.0 46.2 SES 3000/ 80/ 10 – 100

Ultimate Push-In Plug for the best DN 100 PN 1 – 6 150.0 102.0 – 109.0 32.2 52.9 SES 3000/100/ 1 – 6

Raised Face Protection in the

market DN 100 PN 10 – 16 161.3 102.0 – 109.0 32.2 52.8 SES 3000/100/ 10 – 16

DN 100 PN 25 – 100 165.3 102.0 – 109.0 32.2 52.7 SES 3000/100/ 25 – 100

• Single push application and DN 125 PN 1 – 6 180.0 126.5 – 133.5 33.0 50.0 SES 3000/125/ 1 – 6

accurate fitting in a matter of

seconds DN 125 PN 10 – 100 188.0 126.5 – 133.5 33.0 50.0 SES 3000/125/ 10 – 100

• Can be applied to flanges with DN 150 PN 1 – 6 204.0 153.9 – 161.0 32.2 52.7 SES 3000/150/ 1 – 6

dry, clean, cold, oily or wet DN 150 PN 10 – 16 216.0 153.9 – 161.0 32.2 52.7 SES 3000/150/ 10 – 16

surface !

• Manufactured from durable and DN 150 PN 25 – 100 220.0 153.9 – 161.0 32.2 52.7 SES 3000/150/ 25 – 100

impact resistant nylon

• Heavy duty design for positive ANSI

gripping power and strong fit

• Fits flanges according to 1.“ 150 – 300 lbs. 52.0 26.0 – 31.0 24.3 41.5 SES 3000/ 1.“ / 150 – 300

DIN 2627-2638, BS 5504 and 1.1/4“ 150 – 300 lbs. 65.0 34.5 – 39.5 28.0 45.0 SES 3000/ 1.1/4“ / 150 – 300

ANSI 16.5 1.1/2“ 150 – 300 lbs. 75.0 40.5 – 45.5 28.0 45.0 SES 3000/ 1.1/2“ / 150 – 300

2.“ 150 – 300 lbs. 92.0 52.5 – 56.5 28.0 45.0 SES 3000/ 2.“ / 150 – 300

2.1/2“ 150 – 300 lbs. 105.0 62.0 – 67.0 28.0 45.0 SES 3000/ 2.1/2“ / 150 – 300

3.“ 150 – 300 lbs. 128.0 77.5 – 83.0 28.0 46.0 SES 3000/ 3.“ / 150 – 300

4.“ 150 – 300 lbs. 161.5 102.0 – 109.0 32.3 52.8 SES 3000/ 4.“ / 150 – 300

5.“ 150 – 300 lbs. 188.0 126.5 – 133.5 33.0 50.0 SES 3000/ 5.“ / 150 – 300

6.“ 150 – 300 lbs. 218.0 153.9 – 161.1 33.0 50.0 SES 3000/ 6.“ / 150 – 300

Should your requirements not be shown please ask for a separate quotation.

PROTEC products and specifications are subject to improvement and change without notice.

200 0191 442 42 42 0191 442 42 22 www.protecinfo.co.uk